ASTM D1938

Trouser Tear-Propagation Test on Plastics

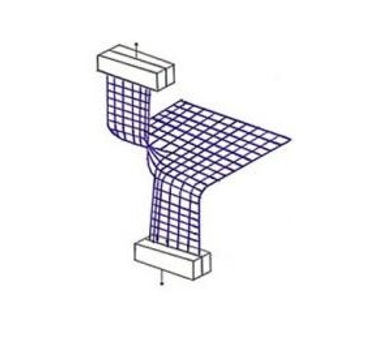

Sample Cutting Die for Cutting a "Trouser"-Like Specimen

Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method - PDF

ASTM D1938 is the standard test method for measuring the tear resistance of plastic films, sheets, and other flexible materials using the trouser tear method. This test simulates conditions where materials are subject to splitting or tearing in real-world applications—especially in packaging, films, liners, and flexible laminates.

This article covers the purpose and scope of ASTM D1938, details the required testing equipment and procedure, and provides guidance for interpreting results and comparing related standards.

What is ASTM D1938?

ASTM D1938, titled "Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method," measures the force required to propagate a tear through a pre-cut sample shaped like a pair of trousers.

Unlike initiation tear tests (like ASTM D1004), the trouser tear method evaluates propagation resistance, meaning how much force it takes to continue tearing once a split has already formed. This makes ASTM D1938 ideal for quality control and material selection when dealing with flexible plastics and films.

Scope and Applications

ASTM D1938 applies to a wide variety of materials, including:

-

Polyethylene and polypropylene films

-

PVC and PET sheeting

-

Multilayer packaging films

-

Rubber-like thermoplastics and elastomers

-

Nonwovens and industrial liners

Typical industries using this method include:

-

Flexible packaging (bags, pouches, liners)

-

Medical packaging (IV bags, pouches, wraps)

-

Agricultural films

-

Construction and roofing membranes

-

Textile laminates and composite sheet goods

This method is valuable for assessing durability, toughness, and performance in the presence of nicks, notches, or minor cuts.

Test Specimen Preparation

Each specimen is shaped like a pair of trousers: a long rectangular sheet with a pre-cut slit dividing one end into two legs.

Standard Dimensions:

-

Overall length: 76 mm (3 in) minimum

-

Width of each leg: 25 mm (1 in)

-

Slit length: 43 mm (1.7 in)

-

Thickness: 0.01 to 1.5 mm (typically)

The slit should be cut cleanly using a razor blade, die, or precision cutter to ensure consistent starting points. The remaining unslit portion must remain intact and free of defects.

Required Testing Equipment

1. Universal Testing Machine (UTM)

A standard tensile testing machine is used to apply the separating force to the two “legs” of the specimen.

Recommended configuration:

-

Load capacity: 1 kN to 10 kN (depending on material toughness)

-

Crosshead speed: 250 mm/min (default per ASTM D1938)

-

Load cell resolution: ±1% or better

2. Grips

The specimen legs are held in pneumatic or mechanical vise grips, one for each arm of the “trouser.” Proper alignment is critical to prevent asymmetrical tearing.

Grips should:

-

Be aligned vertically and symmetrically

-

Have rubber-faced jaws to prevent slippage

-

Apply consistent clamping pressure

3. Software and Data Acquisition

The testing machine software should record force vs. extension in real time and allow identification of average tearing force over a stable region of the curve.

ASTM D1938 Test Procedure

-

Conditioning

-

Condition specimens as needed (e.g., 23°C and 50% RH for 40 hours) per ASTM D618.

-

-

Specimen Setup

-

Mount each leg of the trouser in the testing machine grips.

-

Ensure vertical alignment with no pre-tension on the specimen.

-

-

Test Execution

-

Start the machine and apply tension at a constant rate of 250 mm/min.

-

Record the force required to continue tearing the specimen.

-

-

Data Recording

-

Focus on the steady-state tearing region (after initiation).

-

Ignore force spikes at the beginning or end of the tear.

-

Tear Resistance Calculation

The average tearing force is calculated over the stable tear region of the curve.

Tear resistance (T) is reported in units of:

-

Newtons (N)

-

Pounds-force (lbf)

No complex formula is required; simply calculate the average force during the propagation region. Report the mean and standard deviation across multiple specimens (minimum of 5 per ASTM D1938).

Benefits of ASTM D1938

-

Simulates real-world tear propagation conditions

-

Works on thin and flexible materials where other tests are unreliable

-

Easy to perform using standard tensile testers

-

Minimal sample preparation compared to more complex peel tests

-

Offers repeatable results ideal for quality control and material comparison

Related ASTM Standards

ASTM D1938 is focused on propagation tear of flexible materials. Other related test methods include:

-

ASTM D1004 – Tear initiation resistance (Graves tear)

-

ASTM D1922 – Pendulum test for tear resistance

-

ASTM D624 – Tear strength of vulcanized rubber and thermoplastics

-

ASTM D882 – Tensile testing of thin plastic sheeting

These tests offer complementary data depending on whether initiation or propagation tear strength is more relevant for the application.

Conclusion

ASTM D1938 provides a reliable and repeatable way to measure the tear-propagation resistance of flexible plastic materials using the trouser tear method. It’s widely used in packaging, medical, industrial, and construction industries to evaluate performance, durability, and safety of plastic films and sheets.

If you’re working with flexible materials, ASTM D1938 is an essential standard for your QA program, material development process, or regulatory compliance testing.