Peel Testing Grips and Fixtures

Advanced manufacturing practices such as lightweighting and automated assembly have led to above trend growth in the adhesives industry. In 2016, the global market for adhesives stood at roughly $25 billion USD with 10 million tons of output. As the market has matured, a myriad of ASTM peel testing procedures have been developed in order to test the strength of the manufactured adhesives.

The most popular and simplest procedures involve peeling a tape at an angle of 90 degrees or 180 degrees in relation to a substrate. The picture below shows the load direction for the 90, 180, and T-peel tests.

90 degree Peel Fixture

180 degree peel test fixture

ASTM D3167 Peel Grip

ASTM D1781 Climbing Drum Peel Grip

ASTM D3811

Vise Grips for peel testing

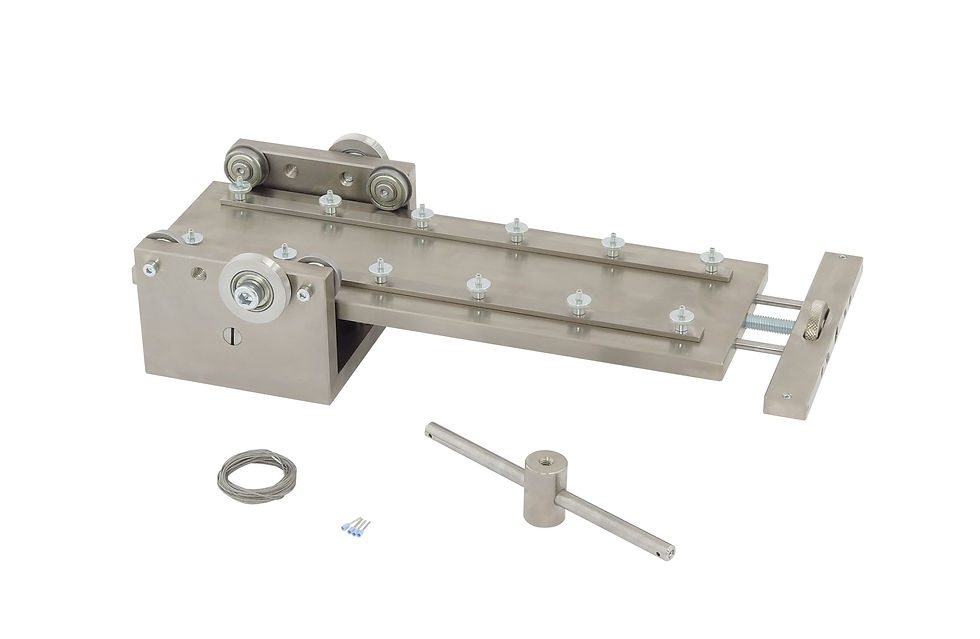

90 Degree Peel Fixture

The 90 degree fixture is mentioned in several ASTM Standards including D3330, D903, and D6862. The fixture uses a spring loaded sliding table in order to maintain the 90 degree peel angle throughout the entire test. A small series of cables and pulleys are used to pull the stage. These cables are mounted behind the load cell soas to not disrupt the peel strength measurement.

180 Degree Peel Fixture

The 180 degree peel strength test procedure is used to test the maximum peel strength. Tapes have the most gripping force when peeled at 180 degrees.

ASTM D3167

The floating roller peel test fixture is used for ASTM D3167. The subtrate board is mounted with the tape facing down. The tape is pulled through the center roller at roughly 90 degrees. Other angles are also available including those for DIN 53289, EN 1464, and ISO 4578.

ASTM D1781

The Climbing Drum Peel Fixture is used to test adhesives used in sandwich cores composite structures. The test can also be used for tapes, but this is less popular. The drum is mounted as the bottom grip and a vise grip is used as the top grip to pull the substrate vertically.

ASTM D3811

This test is used to measure the peel strength of an entire roll of tape. The tape roll is mounted onto a spinning mandrel drum and the tape end is pulled from the top grip. Standard tape rolls have a 3" inner diameter, however designs for different sized rolls are also available such as those for DIN 53357

ISO 10373

The ISO 10373 fixture is used to test the peel strength of credit cards and identification cards. These cards often use stickers and adhesives for logos, PIN #'s, and the signature area on the back of the card.

Tensile Vise Grips

Vice grips are one of the most popular type of general use tensile grip. They are used in Adhesive tests to attach onto the end of the tape and pull it. Tensile grips are needed for teh T-Peel test as described in ASTM D1876. In some cases, wedge grips can be used too. Pneumatic Grips are used quite often as they help to standardize the testing procedure between different technicians.

Variable Motorized Fixture

Economical 90 degree peel system