ASTM D6484

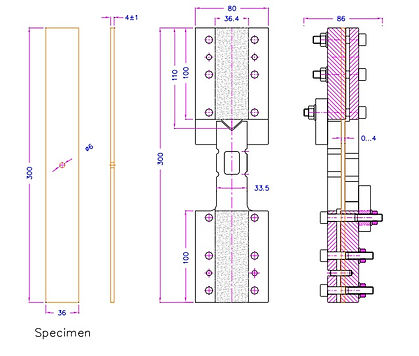

Open-Hole Shear Fixture

Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix Composite Laminates - PDF

ASTM D6484 is the standard test method used to determine the open-hole compressive strength of fiber-reinforced polymer matrix composite laminates. The method is commonly applied in aerospace, automotive, and industrial applications where fasteners or cutouts are present in structural components.

This guide explains the purpose and scope of ASTM D6484, details the testing equipment and fixture setup, outlines the test procedure, and compares it to related test standards for composites.

What is ASTM D6484?

ASTM D6484/D6484M – Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix Composite Laminates evaluates how a composite material behaves under compressive loading when a stress concentrator—specifically a central hole—is introduced.

Fastener holes and cutouts in composite structures cause significant stress concentrations. ASTM D6484 simulates this condition to assess:

-

Open-hole compressive strength (OHC)

-

Failure mechanisms due to stress concentration

-

Material behavior under realistic structural conditions

This method is crucial for engineers designing bolted or riveted composite joints, where accurate understanding of the effect of a hole under load is essential.

Scope and Applications

ASTM D6484 is widely used in:

-

Aerospace structural design and material qualification

-

Automotive crash structures using carbon fiber

-

Defense components using high-strength woven laminates

-

Industrial and recreational composite product testing

It is applicable to:

-

Carbon, glass, aramid, or hybrid fiber-reinforced polymer composites

-

Unidirectional, multidirectional, or woven layups

-

Laminates with or without toughened matrices

Specimen Geometry

The ASTM D6484 test uses a rectangular laminate specimen with a precision-machined circular hole at its center.

Typical dimensions (per standard):

-

Length: 140 mm (5.5 in)

-

Width: 36 mm (1.4 in)

-

Thickness: 2–10 mm depending on the laminate

Center Hole

-

Diameter: 6 mm (0.25 in) for standard specimens

-

The hole must be precisely machined (typically via CNC or waterjet)

-

No delaminations or thermal damage from drilling

The hole simulates a bolt or fastener location and induces a stress concentration, leading to premature failure in compression—exactly what this test is designed to analyze.

Required Testing Equipment

1. Universal Testing Machine (UTM)

The UTM applies compressive force to the specimen through custom-designed fixtures.

-

Load capacity: Typically 50 kN to 250 kN depending on material

-

Load cell accuracy: ±1% or better

-

Crosshead speed: 1.25 mm/min (standard)

Both electromechanical and servo-hydraulic systems can be used for this test.

2. Compression Fixture

A specialized fixture is used to grip and load the specimen without introducing bending. The fixture design helps maintain axial alignment and distribute the load evenly.

Key features:

-

Flat loading plates with anti-buckling support

-

Side guides or clamping to prevent lateral displacement

-

Adaptable to different specimen sizes

3. Strain Measurement (Optional)

Strain gages or non-contact extensometers may be used to monitor strain during loading, though only peak load is required to determine OHC strength.

ASTM D6484 Test Procedure

-

Specimen Preparation

-

Machine a precision 6 mm (or as specified) hole at the center.

-

Ensure edges are clean and free of delamination.

-

Dry and condition specimens if required by the test environment.

-

-

Fixture Setup

-

Align the specimen within the fixture.

-

Apply preload to ensure full contact without introducing bending.

-

-

Compression Loading

-

Apply force at a constant rate of 1.25 mm/min until specimen failure.

-

Record the maximum compressive load.

-

-

Calculation

-

To calculate the open-hole compressive strength, use the following formula:

Divide the maximum load by the product of the specimen thickness and the specimen width minus the hole diameter.

In equation form:

OHC strength = Pmax / [(w – d) × t]

Where:

Pmax is the maximum load

w is the specimen width

d is the hole diameter

t is the specimen thickness

-

-

Failure Mode Documentation

-

Photograph and document fracture surfaces.

-

Note whether failure occurred in bearing, net section, or by delamination.

-

Benefits of ASTM D6484

-

Direct simulation of realistic fastener-induced stress conditions

-

Useful for design allowables and failure mode analysis

-

Accommodates a wide range of composite thicknesses and layups

-

Provides repeatable and representative compressive strength data

Related Composite Testing Standards

While ASTM D6484 is specific to open-hole compression, other related standards include:

-

ASTM D5766 – Open-hole tensile test for composite laminates

-

ASTM D6482 – Bearing response of composites (single-lap shear test)

-

ASTM D6641 – Compression strength of composites using combined loading (non-hole test)

-

ASTM D3039 – Standard tensile testing for composite laminates

These standards are often used in conjunction to fully characterize a composite laminate under various stress conditions—especially where holes, fasteners, or out-of-plane loads are involved.

Conclusion

ASTM D6484 is a critical method for determining the open-hole compressive strength of composite laminates, simulating the behavior of a structure under realistic fastening and joint conditions. The method's reliable fixture design, precise hole placement, and focus on compressive failure mechanisms make it a go-to standard in aerospace and high-performance engineering environments.

For engineers and quality assurance professionals working with composites, ASTM D6484 provides the data necessary to ensure safe, lightweight, and efficient composite structure designs.

Need ASTM D6484 Testing Equipment?

We supply universal testing machines, compression fixtures, and all required components for compliant ASTM D6484 testing. Contact us for expert guidance and a custom quote.