.jpg)

Manual Tensile Testers

Products >> Manual Tensile Testers

Manual Force Tensile Testers – Hand-Crank & Manual Pull Testing Machines

Precision Tensile Testing with Manual Force Test Stands from Universal Grip Co.

Manual force tensile testers—also called hand-crank tensile testers or mechanical tensile test stands—are cost-effective, highly reliable solutions for performing tensile, compression, peel, and flexural tests on a wide range of materials.

At Universal Grip Co., we supply manual tensile testing machines engineered for ASTM, ISO, and other international standards. Our Manual Force Testers typically ship with a precisely calibrated analog force gauge (pictured below.) And as always all of our grips, fixtures, and adapters, whether standard or custom optimized can fit onto any Manual Force Tensile Testing Machine dependent upon your specific testing needs.

Basic Manual Force tester with Analog Gauge

(up to 2000 lbs. of Force without the use of a motor!)

What is a Manual Force Tensile Tester?

A manual force tensile tester is a (manual) universal testing machine (UTM) operated by a manual crank, lever, or wheel, allowing the user to control crosshead movement without an electro-motor. This provides:

-

High operator control for delicate specimens

-

Lower equipment costs compared to motorized testers

-

Portable, low-maintenance testing capability

These testers are widely used in quality control laboratories, production floors, educational environments, and field testing where portability, budget-friendliness, and precision are equally important.

Features of Universal Grip Co.’s Manual Tensile Testers

-

Load Capacity Options: From 100 N (25 lbf) to 9 kN (2,000 lbf)

-

Accuracy: ±0.25% or better of indicated load (Meets ASTM Standards)

-

Travel Range: Adjustable to accommodate various specimen sizes (Generally 6")

-

Grip Compatibility: Works with most Universal Grip Co. grips and fixtures

-

Display Options: Analog dial gauges or advanced digital force indicators

-

Custom Fixtures: Engineered to match ASTM, ISO, TAPPI, and DIN standards

Common Applications & Test Standards

Our manual testers are adaptable for multiple test types, including:

Tensile Testing

-

ASTM D5034 – Grab tensile strength of textiles

-

ASTM D638 – Tensile properties of plastics

-

ASTM E8 – Tensile testing of metals

Compression Testing

Peel, Shear & Adhesion

-

ASTM D903 – Peel resistance of adhesives

-

ASTM D1876 – T-peel of adhesives

Flexural & Bending

-

ASTM D790 – Flexural properties of plastics

-

ISO 178 – Flexural strength of rigid materials

Benefits of Choosing a Manual Tensile Tester

-

Lower Cost – Ideal for budget-conscious labs and production floors

-

Full Operator Control – Perfect for fragile or irregular samples

-

Compact & Portable – Small footprint for easy relocation

-

Low Maintenance – Minimal electronics means reduced downtime

-

Versatile – One frame can handle multiple test setups

Why Buy from Universal Grip Co.?

We provide complete turnkey tensile testing solutions:

-

Machine + Grips + Fixtures + Load Cells all from one supplier

-

Custom Engineering – Designed for unique materials and shapes

-

Calibration Services – Maintain compliance and accuracy

-

Expert Consultation – Decades of combined materials testing experience

-

Full Range of Accessories – Extending your tester’s capabilities

-

Wide Catalog of Manual Force Testing Machine Options -

-

From basic jigs to more sophisticated options including a Manual Testers from our Mark-10 line.

-

When you buy a manual tensile tester from Universal Grip Co., you’re not just getting a machine—you’re getting a fully supported testing solution.

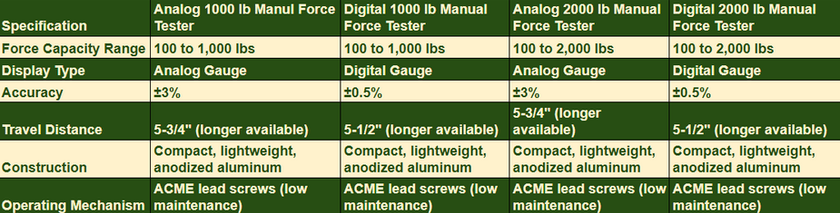

Manual Force Testers - Selection Guide

Additional Features (Both Models)

-

Hardware: Stainless steel construction

-

Gauge Protection: Durable stainless steel gauge guard

-

Interface: Male 5/16"-18 grip/fixture connection

-

Calibration: Includes calibration certificate

-

Grips & Fixtures: Sold separately for both models

Key Differences

-

Force Capacity: 1000 lb models max at 1,000 lbs vs 2000 lb models max at 2,000 lbs

-

Accuracy Improvement: Digital versions offer 6x better accuracy (±0.5% vs ±3%)

-

Travel Distance: Analog models have slightly longer travel (5-3/4" vs 5-1/2")

-

Digital readout Gauge is slightly Bigger than the Analog *see Cut Sheets*

Request a Quote for a Manual Tester

Get a custom quote for your manual tensile testing machine today.

📞 Call: (978-882-1480)

✉ Email: (christhomas@universalgripco.com)

🌐 Visit: www.universalgrip.com

Universal Grip Co. – Your Partner in Precision Testing and Grip Solutions

Manual Force Tensile Testers – FAQs

... Q1: What is a manual force tensile tester used for? A manual force tensile tester measures the strength and elongation of materials such as textiles, plastics, metals, rubber, and composites. It can also perform compression, peel, shear, and flexural tests depending on the grips and fixtures used. Q2: How does a manual tensile tester work? The operator uses a hand-crank or lever to apply force to the test specimen. A load cell measures the applied force, and displacement is recorded using either analog or digital measurement devices. This setup allows precise, repeatable testing without a motorized drive. Q3: What are the advantages of a manual tensile tester over a motorized one? Manual testers are more affordable, portable, and easier to maintain. They give the operator full control of the test speed, making them ideal for delicate samples or low-volume testing environments. Q4: Are manual tensile testers ASTM-compliant? Yes. When paired with the correct grips and fixtures, manual tensile testers from Universal Grip Co. can be configured to meet ASTM, ISO, TAPPI, and DIN standards for a variety of materials and test types. Q5: Can I customize a manual tensile tester for my specific application? Absolutely. Universal Grip Co. offers full customization options, including load capacity, frame style, grips, fixtures, adapters, and measurement systems tailored to your exact testing needs. Q6: What load capacities are available? Our manual tensile testers are available in capacities ranging from 500 N (112 lbf) to 5 kN (1,100 lbf), with custom options for higher capacities if required. Q7: Do you provide calibration and maintenance services? Yes. We offer calibration services to keep your tester accurate and compliant, along with maintenance support to extend the life of your equipment.

Manual Tensile Tester Products

30 lb. Manual Tensile Tester

This 30 lb. or 150 Newton Tensile Tester is only capable of compression testing. Max travel with this test stand is 1.5" or about 40mm. The adjustable hand lever can be repositioned along the vertical bar to accommodate a range of different samples. Low weight, low footprint tester. Perfect for portable applications or crowded work areas.

50 lb. Manual Tensile Tester

The 50 lb. or 250 Newton tensile testing machine is slightly taller than the 30 lb. unit. The lever is used to move the crosshead and sample 1". This unit can be outfitted with a force gauge and different grips to change the operation. The 50 lb. tester works in both tensile & compression mode and can be configured with a digital or analog travel indicator to measure displacement up to 1".

100 lb. Manual Tensile Tester

The 100 lb. or 0.5 kN manual tensile tester uses a hand wheel to move the crosshead of the apparatus. The hand wheel is much more precise than the hand lever giving the user more control of the movement. The tester can be outfitted with a tensile or compression force gauge and with various grips according to the exact test procedure required.

200 lb. Manual Tensile Tester

The 200 lb. or 1 kN manual tensile testing machine is a verstatile platform capable of performing a wide variety of ASTM & ISO style tests. The system can be configured for either tensile or compression mode. A large selection of grips & fixtures are compatible with this unit. A digital travel gauge can be included for precise displacement & strain measurement.

750 lb. Manual Tensile Tester

The lever-operated manual test stand delivers up to 750 lbF (3.75 kN) of tensile or compressive force for quick-action testing. Built with rugged, precision components, it’s durable enough for the factory floor yet accurate for laboratory use. The lever adjusts in 30° increments, providing smooth 6 in. travel through its precision rack and pinion system. Available in vertical or horizontal configurations, it pairs with force gauges and grips to form a complete push/pull testing system.

1,000 lb. Horizontal Manual Tensile Tester

The horizontal test stand is designed for up to 1,000 lbF (5 kN) of tension or compression testing, combining strength with precision. Its large hand wheel allows effortless operation even under high loads, while the precision Acme screw and nut provide smooth, consistent motion. The solid metal base includes a storage pocket and mounting holes for easy bench setup, and the stand is available in both vertical and horizontal configurations.

1,000 lb. Vertical Manual Tensile Tester

The 1,000 lb. vertical manual test stand is designed for applications such as spring testing, destructive testing, and product integrity testing up to 1,000 lbF (5,000 N). It features a large side-mounted hand wheel for effortless operation and a rigid 3" x 3" column for stability. The removable steel loading surface with threaded holes allows flexible fixture and grip mounting, while the solid metal base includes a storage pocket and bench-mounting holes. Available in both vertical and horizontal configurations.