ASTM D1781 Climbing Drum Peel Test Fixture

- Mark Edwards

- Jan 23

- 7 min read

ASTM D1781: Standard Procedures for Climbing Drum Peel Testing of Adhesives

Introduction to ASTM D1781

Peel adhesion testing is a critical method for evaluating the performance of bonded assemblies, particularly where flexible or semi-rigid adherends are involved. Among the various peel test methods defined by ASTM International, ASTM D1781 is unique in its use of a climbing drum peel configuration, which provides a controlled and repeatable means of measuring adhesive peel resistance under a constant peel angle.

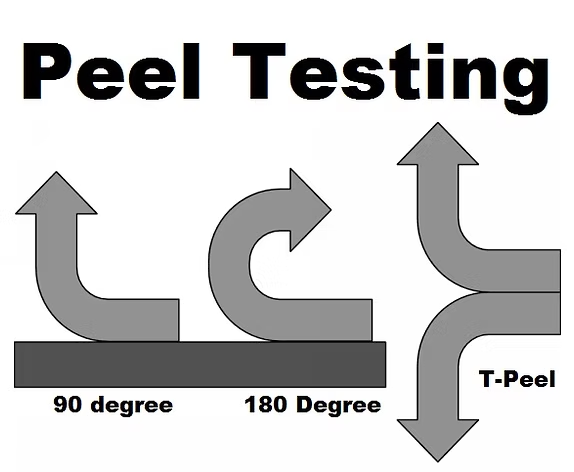

ASTM D1781, Standard Test Method for Climbing Drum Peel Test for Adhesives, is widely used to characterize the peel strength of structural and semi-structural adhesives bonded to relatively stiff substrates. The method is especially valuable when traditional flat peel tests, such as 90-degree or 180-degree peel methods, produce inconsistent results due to bending stiffness or peel arm instability.

This article provides a comprehensive technical overview of ASTM D1781, including the principles of the climbing drum peel test, required equipment, specimen preparation, grips and fixtures, data analysis, and best practices for achieving reliable and repeatable peel adhesion results.

Overview of ASTM Adhesive and Peel Testing Standards

ASTM maintains an extensive suite of adhesive testing standards designed to evaluate bond performance under different loading conditions. These include tensile, shear, cleavage, and peel test methods, each offering insight into different aspects of adhesive behavior.

Peel testing standards are particularly sensitive to test geometry, substrate stiffness, and loading angle. Common ASTM peel standards include 180-degree peel tests, T-peel tests, and floating roller peel tests. ASTM D1781 differs from these methods by employing a rotating drum that maintains a near-constant peel angle and minimizes changes in bending stress during testing.

Within the broader framework of ASTM adhesive standards, ASTM D1781 is often selected when:

The bonded substrate is relatively stiff

Stable peel conditions are required

Accurate average peel force measurements are critical

The test must minimize operator-dependent variability

As a result, ASTM D1781 is frequently used in adhesive qualification programs, comparative material studies, and quality control testing.

Scope and Purpose of ASTM D1781

The primary purpose of ASTM D1781 is to determine the peel resistance of adhesive bonds using a climbing drum apparatus. The test measures the force required to progressively peel one adherend from another while maintaining controlled geometry and loading conditions.

ASTM D1781 is applicable to a wide range of adhesive systems, including:

Structural adhesives

Pressure-sensitive adhesives

Film adhesives

Laminating adhesives

The method is commonly used with metal substrates, polymer laminates, and composite materials, provided the adherends meet the stiffness requirements necessary for stable drum peeling.

ASTM D1781 is not intended to measure shear strength or tensile bond strength. Instead, it evaluates the resistance of an adhesive bond to peeling forces, which are often more representative of real-world service conditions such as edge loading, delamination, or progressive bond failure.

Principles of the Climbing Drum Peel Test

The climbing drum peel test is designed to apply a consistent peeling action by wrapping the bonded specimen around a rotating cylindrical drum. As the test progresses, the drum “climbs” along the bonded interface, maintaining a nearly constant peel angle and minimizing changes in bending stiffness.

During the test:

One adherend remains bonded to the drum

The free peel arm is pulled by the testing machine

The drum rotates freely as the adhesive bond progressively fails

This configuration offers several advantages over flat peel methods. The drum supports the bonded adherend, reducing unwanted bending stresses, while the rotating motion helps stabilize the peel front. As a result, force fluctuations caused by substrate stiffness or peel arm instability are significantly reduced.

The measured peel force reflects the combined effects of adhesive properties, substrate surface preparation, adhesive thickness, and bond uniformity.

Test Apparatus and Equipment Requirements

The primary piece of specialized equipment required for ASTM D1781 is the climbing drum peel fixture. This fixture is typically mounted to the base of a universal testing machine and consists of several key components:

A cylindrical drum with a defined diameter

A specimen clamping or attachment mechanism

Low-friction bearings to allow free rotation

Alignment guides to maintain consistent peel geometry

Fixture rigidity and dimensional accuracy are critical. Any resistance to drum rotation or misalignment can introduce errors into the measured peel force. The drum diameter must be consistent and appropriate for the specimen dimensions specified in the standard.

The fixture must be securely mounted to the test frame to prevent movement during testing. Routine inspection and maintenance of bearings and rotating surfaces are essential to ensure consistent performance.

Universal Testing Machines for ASTM D1781

Although ASTM D1781 focuses on peel testing, it still relies on a universal testing machine (UTM) to apply controlled displacement and measure force. The UTM must be capable of low-force, high-resolution measurements, as peel forces are often significantly lower than tensile or shear loads.

Key requirements for UTMs used in ASTM D1781 include:

Adequate load resolution for low-force measurements

Smooth crosshead motion with minimal vibration

Accurate and traceable load cell calibration

Precise crosshead speed control

Load cell selection is particularly important. Using a load cell with excessive capacity can reduce force resolution and increase noise in the data. Selecting a load cell sized appropriately for expected peel forces improves measurement accuracy and repeatability.

Grips and Fixtures Used in ASTM D1781

Grips play a crucial role in ASTM D1781 testing, particularly in securing the free peel arm of the specimen. Improper gripping can lead to slippage, peel arm damage, or artificially low peel force measurements.

Common grip types used in climbing drum peel testing include:

Mechanical wedge grips for thicker peel arms

Pneumatic grips for thin or flexible adherends

Rubber-faced or smooth grips to prevent tearing

Grip alignment is critical. The peel arm must be centered and aligned with the direction of applied load to avoid twisting or uneven peeling. Misalignment can introduce additional stresses that distort the measured peel force.

The climbing drum fixture itself functions as a specialized support fixture, and its interaction with the specimen must be carefully controlled. Any play or resistance in the drum mechanism can significantly affect test results.

Specimen Preparation and Geometry

Specimen preparation is one of the most significant contributors to variability in peel test results. ASTM D1781 provides general guidance on specimen geometry, but the specific dimensions and materials are often dictated by the application or material specification.

Key specimen preparation considerations include:

Consistent specimen width and bonded area

Uniform adhesive thickness

Proper surface preparation of adherends

Controlled adhesive application and curing

Surface preparation methods such as cleaning, abrasion, chemical treatment, or priming must be documented and consistently applied. Variations in surface condition can dramatically affect peel strength and failure mode.

After preparation, specimens are often conditioned under controlled temperature and humidity prior to testing. Conditioning ensures that environmental effects do not introduce uncontrolled variability into the results.

Test Setup and Execution Procedure

Executing an ASTM D1781 test requires careful attention to setup and alignment. A typical test procedure includes:

Installing and aligning the climbing drum fixture

Attaching the bonded specimen to the drum

Securing the free peel arm in the grips

Zeroing force and displacement readings

Running the test at the specified crosshead speed

The crosshead speed must be controlled and consistent throughout the test. Sudden changes in speed can cause force spikes or unstable peeling.

Environmental testing, such as elevated temperature or humidity exposure, may require additional equipment and stabilization time. Safety considerations are also important, as peeling can produce sudden releases of stored energy when bonds fail.

Data Collection and Peel Force Calculations

During testing, force and displacement data are continuously recorded. The resulting force–displacement curve typically shows an initial transient region followed by a more stable peel force region.

ASTM D1781 generally requires:

Exclusion of the initial peel initiation region

Calculation of average peel force over a defined distance

Reporting peel strength normalized by specimen width

Data smoothing techniques may be used to reduce noise, but they must be applied consistently and documented. Excessive smoothing can obscure meaningful variations in peel behavior.

Accurate data interpretation requires careful review of force stability, specimen behavior, and failure progression throughout the test.

Failure Modes and Result Interpretation

Understanding failure modes is essential for interpreting ASTM D1781 results. Common failure modes include:

Adhesive failure, where separation occurs at the adhesive–substrate interface

Cohesive failure, where failure occurs within the adhesive layer

Substrate failure, where the adherend itself fails

Each failure mode provides different insight into bond performance. Cohesive failure is often indicative of good adhesion, while adhesive failure may point to surface preparation or compatibility issues.

Visual inspection and photographic documentation of fracture surfaces are strongly recommended. Failure mode analysis adds valuable context to numerical peel strength values and improves the usefulness of test results.

Common Testing Challenges and Troubleshooting

Despite standardized procedures, climbing drum peel testing presents several challenges. Common issues include:

Inconsistent peel force due to drum friction

Specimen slippage in grips

Peel arm tearing or necking

Irregular adhesive thickness

Troubleshooting often involves verifying fixture condition, adjusting grip selection, improving specimen preparation, or refining test parameters. Regular preventive maintenance and operator training significantly reduce recurring problems.

Best Practices for ASTM D1781 Compliance

Achieving consistent and defensible ASTM D1781 results requires a systematic approach to testing. Best practices include:

Standardized specimen preparation procedures

Routine inspection of climbing drum fixtures

Proper load cell and machine calibration

Comprehensive operator training

Documentation is critical for compliance with laboratory quality systems such as ISO/IEC 17025. Clear records of equipment, procedures, and test conditions support data traceability and audit readiness.

Conclusion: Reliable Adhesive Evaluation Using ASTM D1781

ASTM D1781 provides a robust and repeatable method for evaluating peel adhesion using a climbing drum configuration. By controlling peel geometry and minimizing bending effects, the method delivers reliable insight into adhesive bond performance that is difficult to achieve with flat peel tests.

Successful application of ASTM D1781 depends on careful equipment selection, proper specimen preparation, accurate force measurement, and disciplined test execution. When these elements are properly managed, climbing drum peel testing becomes a powerful tool for adhesive qualification, material comparison, and quality assurance.

For laboratories and engineers focused on adhesive performance, ASTM D1781 remains a cornerstone peel test method—one that delivers meaningful, actionable data when executed correctly.

Comments